-

+86-576-82686004

+86-576-82686004

-

[email protected] / [email protected]

[email protected] / [email protected]

1.Key Benefits:

Leak Detection

Design features on the O-ring allows for missed press leak detection when tested correctly using the defined procedure in this manual.

Long Lasting Performance

When installed correctly as per the requirements of this document and other regulatory requirements.

Secure Joint

Secure and durable permanent joint ensures the fitting can not be tampered with.

Fully Certified and Tested

Extensive third party certification and testing offers peace of mind, in addition warranty and insurance is covered by Bada.

Flame Free

Flame free installation means no need for hot works permits and no need to lug around heavy bottles used for brazing.

Reduced Installation Time

Simple, quick and reliable installation translates to reduced labour time.

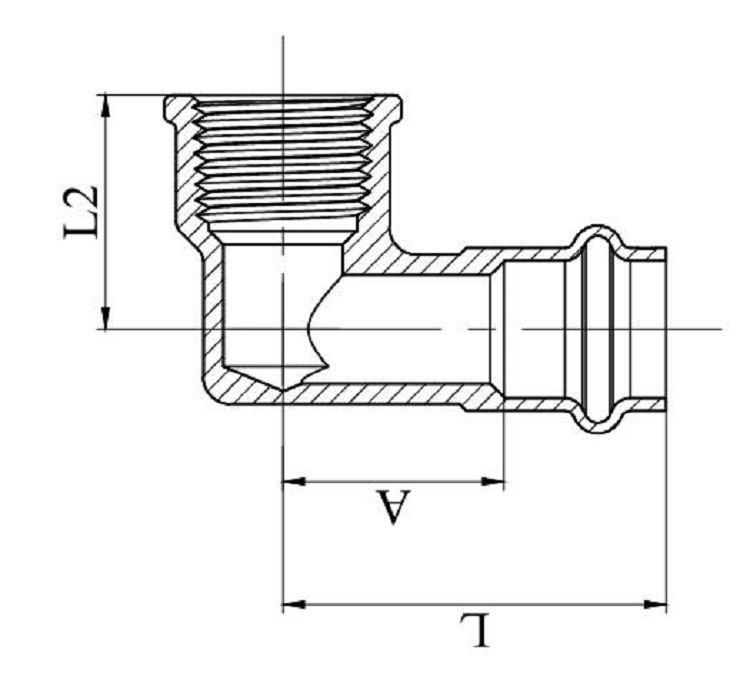

2.Product Specification:

|

Item No. |

Size |

Material |

Certification |

Pcs/bag |

|

70220100 |

3/8" |

C46500/ C69300 |

UPC NSF/ANSI 61 NSF/ANSI 372 |

1 |

3. Leak Before Press:

The precise design Fada® Press fittings allows water or air to pass the sealing element of unpressed fittings, thereby providing a leakage point during the commissioning of the system, when tested using the defined processes below. When the fitting is pressed, the O-ring material compresses, filling the gaps, creating a leak free joint.

Final testing of the system should be conducted in local regulations or requirements.

4. Approvals:

NSF/ANSI 61- Water Quality

NSF/ANSI 372- Lead Free

cUPC® Compliant

5. Accessory:

EPDM sealing element

6. Installation Instruction:

1. Deburring tube ID and OD with file.

2. Check seal for correct fit. Do not use oils or lubricants.

3. Mark proper insertion depth for well sealed.

4. While turning slightly, slide press fitting onto tubing to the marked depth.

The end of tubing must contact stop.

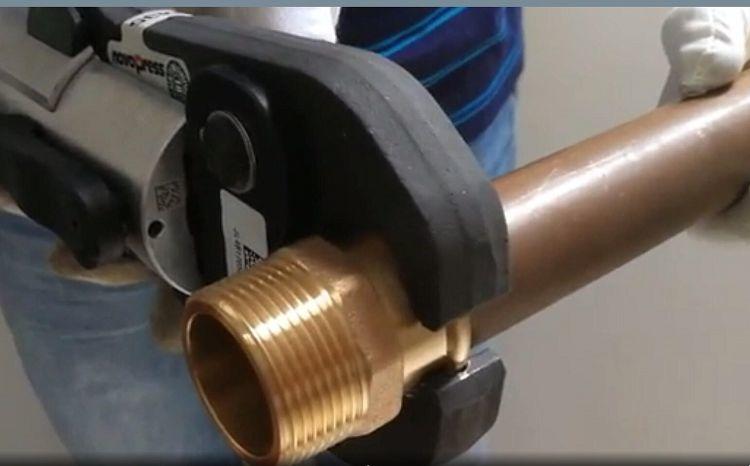

5. Open the jaw and place at right angles on the fitting.

6. Start pressing process and hold the trigger until the jaw has engaged the fittings.

7. Pressing tool and jaws:

8.Tool Maintenance:

Pressing tool, jaws, adaptor jaws and collars are low maintenance, however, to ensure optimal performance and safety there are minimum precautions and maintenance procedures that need to be followed.

Carry out basic inspection of the pressing device and jaws prior to each use to ensure they are clean and free from debris and dirt. The pressing jaws should be visually inspected to ensure there are no cracks. If there are any cracks in the pressing jaws, do not use them, as there is risk of the jaws shattering and potential injury from flying fragments. It is recommended to always wear appropriate eye protection whenever using the pressing device. When inspecting the pressing jaws, also ensure that there are no foreign material deposits and that the contours of the jaw surfaces are in order. Failure to do this may result in damage to the jaws and/or the pressing device.

9. Recommendations:

Fada Lead-free Brass Press 90°Elbow, P x FPT - 1/2"

Fada Lead-free Brass Press Drop Ear 90°Elbow, P x FPT - 1/2"

Fada Lead-free Brass Press Drop Ear 90°Elbow, P x FPT - 3/4"

10. Frequently Asked Questions:

Q: What is press fitting technology?

A: Press fitting technology is a mechanical, solder-less method of tubing joining. No torches or solvents are required to make the permanent water-tight seal. This was introduced in the United States in 1995.

Q: What are the most common errors made when installing s Press Fittings?

A: Not adequately deburring the end of the tubing, and not inserting the tube far enough into the press fitting.

Q: Do I need to lubricate the O-ring?

A: No, the O-ring is pre-lubricated. Using additional lubricants could reduce the longevity of the O-ring and void the warranty. Care should be taken during copper tube insertion to ensure the O-ring does not roll or dislodge.

Taizhou Bada Valve Co., Ltd is professional China wholesale Lead-free Brass Press 90°Elbow Press X FPT - 3/8 Inch suppliers and OEM/ODM company,we focus on manufacturing and exporting various brass/bronze valves, fittings and other plumbing products which located in Luqiao District, Taizhou City. There are 33 primary and intermediate technicists; more than 320 workers; more than 330 sets machining and testing equipments; casting, forging and ect.11 workshops. The bronze casting and machining is our strong suit which is in the leading passion in China. OEM orders are welcome!

Contact Us >>The company insists on seeking credibility with quality and credibility with management. In order to become the most competitive and qualified Lead-free Brass Press 90°Elbow Press X FPT - 3/8 Inch supplier in the world, our production follows 6S and ISO9001-2008 system, and our strategic goal is to build on the basis of high-quality and efficient service.

We adhere to the business ethics of "people-oriented, winning by quality, respecting customers, slow commitment, fast fulfillment", learn from others' strengths, gain profits, gain employee benefits, and repay the society!

In plumbing and piping systems, press fit bronze fittings are widely used for their durability, reliability, and ease of...

In the realm of plumbing and pipeline systems, the Bronze Press Tee stands as a testament to the intersection of style a...

In the dynamic world of plumbing, where safety and sustainability are paramount, lead-free brass solder ball valves stan...

In the realm of piping systems, ensuring a secure and leak-free connection between pipes and fittings is essential for e...