Bronze Ball Valve Craftsmanship On Casting

When manufacturing

brass ball valves, the casting process is a key link that affects the quality and performance of the product. The following are several important aspects that should be paid attention to in the casting process of brass ball valves:

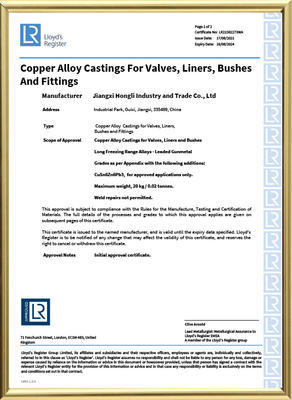

Material Preparation: High-quality brass alloys are selected as raw materials, ensuring that they comply with applicable standards and codes. Materials should undergo strict chemical composition analysis and physical performance testing to ensure their stable quality.

Mold design and manufacturing: The mold is a key factor in the casting process and has a direct impact on the shape, size and surface quality of the product. The mold should be reasonably designed and manufactured with high-precision processing technology to ensure the accuracy and consistency of the product.

Melting and casting: During smelting, the temperature, time, and atmosphere during smelting should be well controlled to ensure the stable quality of the brass alloy melt. Appropriate process parameters should be used during casting, including mold temperature, pouring speed and pressure, etc. to obtain good casting quality.

Heat treatment: Brass ball valves usually require heat treatment after casting to improve their structure and performance. Heat treatment process parameters should be precisely controlled, including heating temperature, holding time and cooling speed, etc., to ensure the mechanical properties and corrosion resistance of the product.

Surface treatment: The surface treatment of brass ball valves has a direct impact on the appearance quality and corrosion resistance of the product. Manufacturers should choose suitable surface treatment methods, such as sanding, polishing, coating, etc., and control the treatment process parameters to ensure the surface quality and corrosion resistance of the product.

Inspection and quality control: During the casting process, the manufacturer should carry out strict inspection and quality control, including an inspection of raw materials, an inspection of product size and shape, an inspection of heat treatment effects, etc. Unqualified products should be dealt with in time to ensure the stability and consistency of product quality.

Process improvement and continuous improvement: Manufacturers should regularly evaluate and improve the casting process of brass ball valves, look for potential problems, and take measures for improvement. Through continuous improvement of process and technology, improve product quality and performance to meet the market.

"Leaded red brass" refers to a type of brass alloy that contains a certain percentage of lead. Red brass, also known as low brass or semi-red brass, is a type of brass that is composed primarily of copper (Cu) with smaller amounts of zinc (Zn) and other elements.

The term "leaded" in "leaded red brass" indicates that the alloy also contains a small amount of lead (Pb). Lead is added to brass alloys to improve machinability and reduce friction during machining and assembly processes. The presence of lead can also Enhance the sealing properties of brass valves by promoting the formation of a tight seal between the ball and the valve seat.

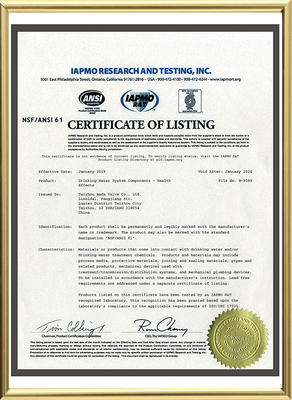

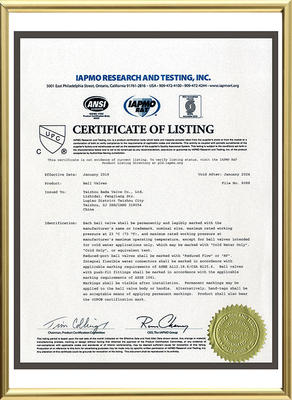

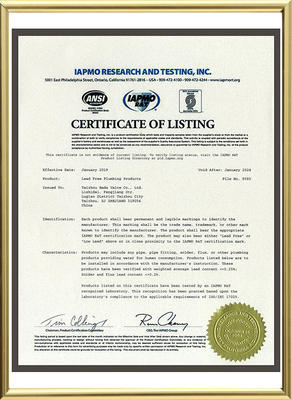

It's important to note that the use of lead in brass alloys has become a concern due to its potential environmental and health hazards. In many regions, there are regulations and standards in place that restrict or limit the use of lead in plumbing and other applications. Therefore, it's essential to understand the composition of brass alloys, including the presence of lead, and comply with applicable regulations and standards when manufacturing and using brass ball valves.

2024/04/26

2024/04/26 2024/04/19

2024/04/19 2024/04/12

2024/04/12 +86-576-82686004

+86-576-82686004

[email protected] / [email protected]

[email protected] / [email protected]

EN

EN

Español

Español